Application, Brewery, Brewery FAQ, Chemical Processing, Commercial, Farm/Barn, Fiberglass Grating, Fibergrate, Frame & Grate Systems, Greenhouse, Home Trench Drain Projects, Kennel, Latest Drainage News, Manufacturer, Residential, Trench Drain Basics, Trench Drain Systems, Uncategorized, Waterworks, Winery, Yard/Lawn/Landscape, Zoo

6 Reasons to Consider Fiberglass Reinforced Plastic

Fiberglass Reinforced Plastic (FRP) is becoming a common building material, but while some areas have been quick to embrace fiber-reinforced polymers, other contractors and plant managers still aren’t convinced. Why should they use fiberglass grating for their railings, walkways and trench drains?

6 Reasons to Choose FRP

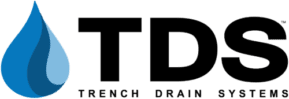

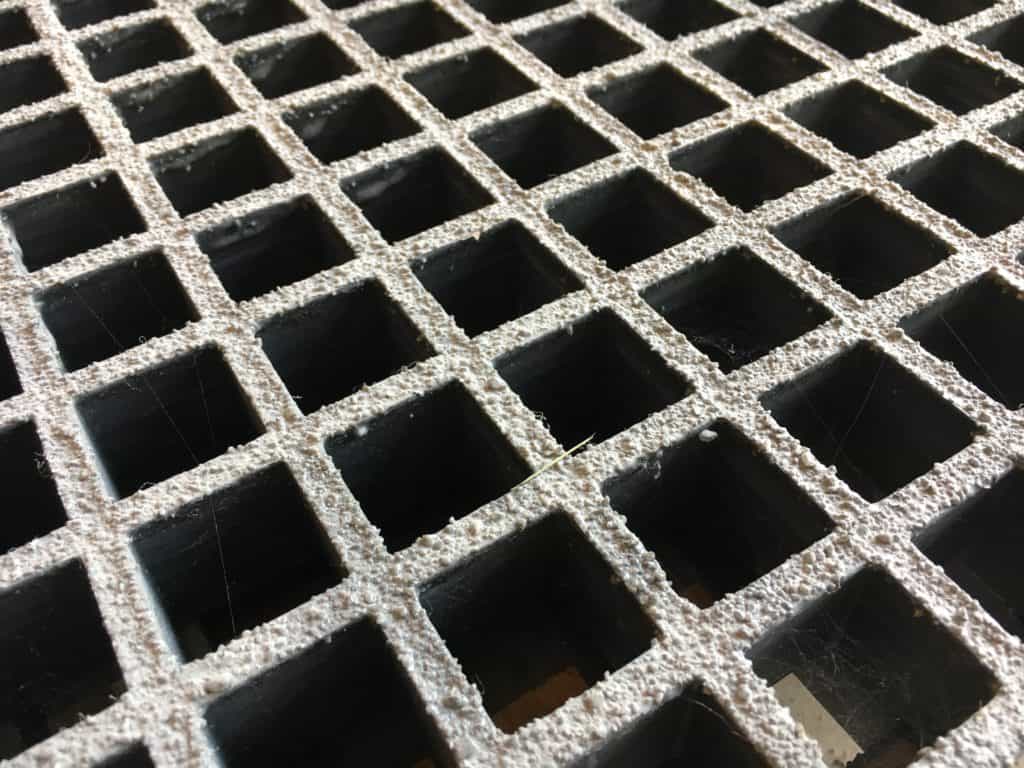

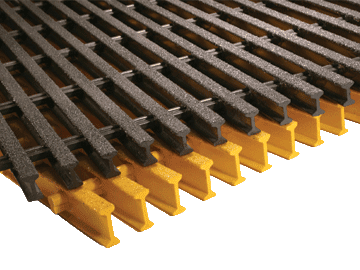

FRP material is a composite made by combining glass fibers with resin. This process gives the grate its strength and creates a corrosive-resistant, non-conductive shield that makes fiberglass grating so popular in utility plants, coastal areas and chemical containment facilities. Fiberglass Reinforced Plastic can be applied with a non-slip coating for walking platforms at water treatment plants.

1 – Capacity

Fiberglass grates have remarkable load capacity – loaded forklifts can drive across a 12” wide fiberglass grate. Ductile iron grates can take a lot of effort and muscle strain to maneuver, consider using lightweight fiberglass grates.

2 – Cost-efficiency

Pound for pound, fiberglass grates cost less than iron. We’re thinking long-term. From a practical sense, fiberglass doesn’t have the same scrap value as cast iron grates and are less likely to be stolen. Fiberglass is a great option If you’re in an area where scrapping is a concern. There’s also a low installation cost since the material is not labor-intensive.

3 – Corrosion

Fiberglass resists corrosion from acids, bases, oxidizing agents, salts and sulfur gasses. It doesn’t stain like galvanized and stainless steels do. Corrosion is temperature-based, increasing with higher temperatures. In these cases, use fiberglass grates made with a high-temperature resistant vinyl ester resin.

4 – Conductivity

Because fiberglass is non-conductive, it is a popular material in utility plant catwalks. Fiberglass grates provide a safe walking space through wet environments where electricity is a serious concern. Because of this, fiberglass grates don’t experience corrosion that happens when two different metals touch while exposed to water. Stainless grating secured with galvanized fittings will weather faster than a fiberglass grate using the same securing mechanisms.

5 – Grit

Fiberglass grating offers a smooth finish along with a wide range of surface textures. Grit selections are perfect for wet or otherwise slippery surfaces. There are coarse selections that can be aggressive for gripping footwear or sand-like light particles that are safe and comfortable for bare feet. This feature is also beneficial for food market displays, fish processing stations, as well as a perfect fit for a lightweight non-slip surface in the boating industry.

6 – Versatility

FRP can be used in a number of areas beyond drainage solutions. There are a wide variety of other opportunities for its usage. It can be used as an architectural feature that provides a privacy screen or blocks the sun, for example.

Zoos and aquariums have used it traditionally as well as within enclosures for all types of animals from sharks to tigers. With its resistance to a variety of chemicals, it’s used as shelving for storing harsh chemicals and corrosive items such as batteries.

You may even find it used as tabletops at a local farmer’s market. It’s perfect for displaying food/fresh fish that may need to have a way to drain off excess water. The possibilities with this product are endless.

Where and How

| Where FRP Is Used: | How FRP Is Used: | |||

| Aquariums/Zoos | Beef/Fish Processing Plants | Access Platforms | Animal Barriers | |

| Beverage Bottling Companies | Bridges (walkways) | Balconies | Battery Storage | |

| Car Washes | Chemical Processing Plants | Boat Landings/Splash Zones | Chemical Storage | |

| Drilling Derricks | Fish Hatcheries | Communication Platforms | Docks & Decking | |

| Freight Yards | Farmers Markets | Feature Walls/Architectural Feature | Fencing | |

| Locker Rooms | Mining Facilities | Fountains & Pools | Observation Platforms | |

| Parks/Water Parks | Pharmaceutical Laboratories | Privacy Screens | Railings | |

| Power Plants | Salt Processing Facilities | Shower Flooring | Stair Treads/Backing | |

| Ships (ladder treads) | Vehicle Maintenance Facilities |

Do you have a project that could benefit from FRP? Visit Trench Drain Systems and check out the selection of Fiberglass Reinforced Plastic (FRP). We have industry experts including an in-house engineering department that are happy to assist with layouts, drawings and/or submittal packages.

Trench Drain Systems is one of the largest distributors in the United States who are committed to providing you with quick solutions to all your surface water runoff problems. Our professional staff can assess your project requirements and quickly offer you competitive pricing and information regarding the products you need. Contact us for a free quote or for further information on drainage solutions visit TrenchDrain.com or DrainageKits.com

Phone: 610-882-3630

Email: [email protected]

Click here for a fast and free quote!